You must be aware of Drager oxygen sensors. Special sensors providing us to stay safe in our workplace ensuring the surrounding air is clean and free from harmful gases. We will cover the significance of oxygen sensors in Drager monitors, their operating principles, and what distinguishes the technology behind them. We will also discuss how we can maintain these sensors so that we get the correct information from them, as well as some common problems with them and solutions to fix them. So let’s take a look and find out more about these key pieces of equipment!

Drager devices have oxygen sensors that are like little helpers — they keep an eye on the air that surrounds us. They can sense when oxygen levels are too low or when there are dangerous gases in the air. Such information is extremely crucial in ensuring our safety while we work and play in places where the air may be poor.

No air was too deep in a mine or too deep in a tunnel, filled with dust, filled with smoke. Drager monitors have oxygen sensors that continuously monitor oxygen levels and warn us if they drop below safe levels. Read This: It protects us from not getting sick or maybe suffocated due to lack of oxygen or poor gases.

Special technology is used in Drager oxygen sensors to determine oxygen level in the environment. A little piece of this is called an electrode which reacts to oxygen and sends signals to the monitor. This data appears on the screen, and it lets us see the oxygen levels without delay. This technology does mean that if there is a problem, we can do something quickly and stay safe.

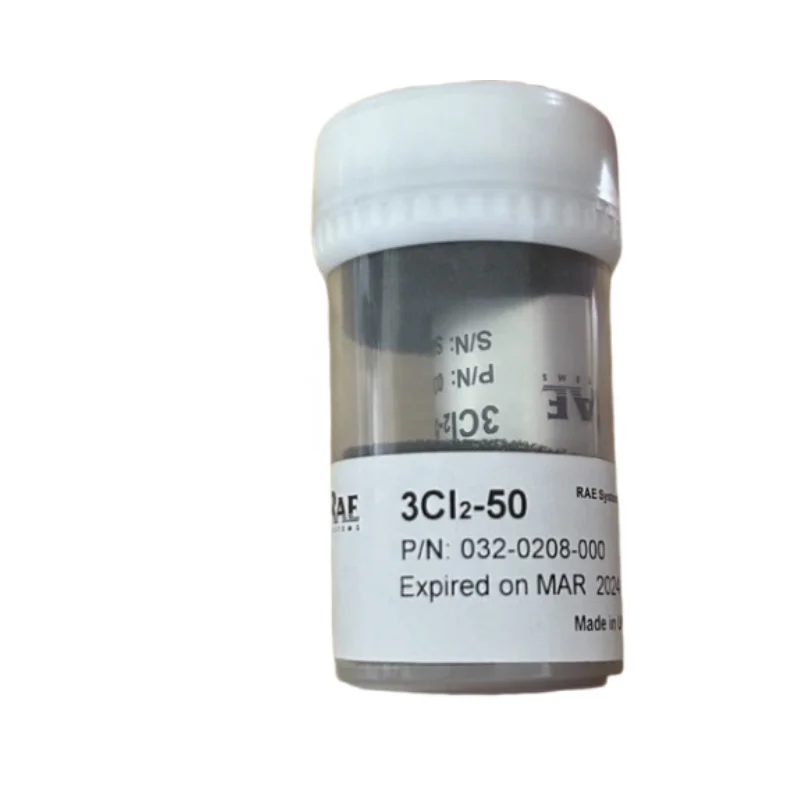

Regular maintenance is important to ensure the proper functioning of the oxygen sensors in Drager equipment. This includes inspecting them for damage, replacing them if they are broken, and ensuring that they provide accurate readings. All this ensures that we can rely on our Drager monitors to notify us should any safety concerns arise.

Oxygen sensors in Drager devices are reliable, but have certain issues. One common problem is known as sensor drift, which occurs when the readings become less accurate as time goes on. You can even try recalibrating the sensor or replace it with a new one to rectify this issue. There is also the issue of sensor fouling, dirt or dust that accumulates on the sensor and causes it to be less efficient. If the sensor is dirty, a gentle cleaning can help it function again.

We provide true one-stop gas detection services, covering everything from initial consultation and system design to on-site installation, ensuring a seamless and integrated safety solution for our clients.

We specialize in developing customized products and solutions to meet liberalized or innovative customer needs, enabling more flexible and efficient operations across various working environments.

With over 1,000 industry-specific scenarios served globally, we possess deep expertise in tailoring gas detection solutions for diverse fields, from petroleum and chemical engineering to environmental protection and clean energy.

Our product range spans seven major series—from sensors and fixed detectors to IoT monitoring platforms—offering both portable and stationary solutions suitable for industrial, commercial, and domestic applications.